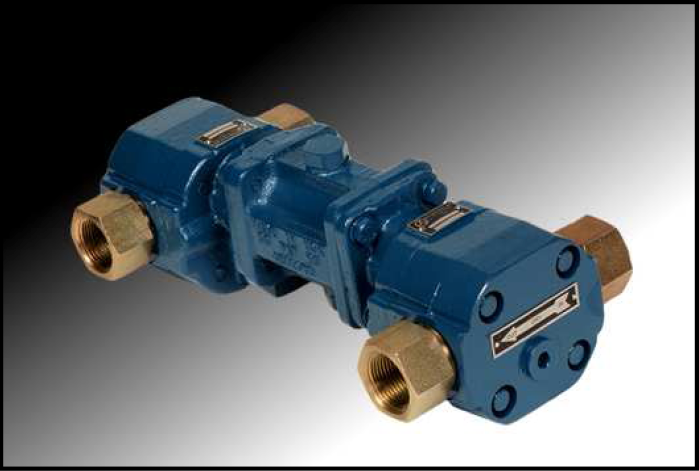

Description

No External Power Source Required

Easily Retrofitted To Existing

Dehydrator Systems

Features and Benefits

Compact Size

- Saves valuable space offshore

- Simplifies transportation

Lightweight

- Enables pumps to hang in piping

- Eliminates additional foundation or supports

Constant Flow

- Eliminates pulsation and vibration

- Improves dehydration efficiency

- Reduces required piping size

Rotary Gear Design

- Sustains high efficiency throughout pump life

- Ensures long operational life with reduced maintenance cost

- Eliminates reciprocating parts and dependency on elastomeric parts which are subject to wear and deterioration

- No slides, pistons, check valves or O-rings to be replaced

Four Frame Sizes Available Modular Construction

- Prevents cross contamination of dry glycol by wet glycol

- Simplifies servicing

- Makes modifications for lower pressures or increased flow rates simple and economical

Optional Flo-Gage

- Accurately measures circulation rates

- Provides environmentally safe means to bleed-off air to prime the pump at start up

Flow Charts

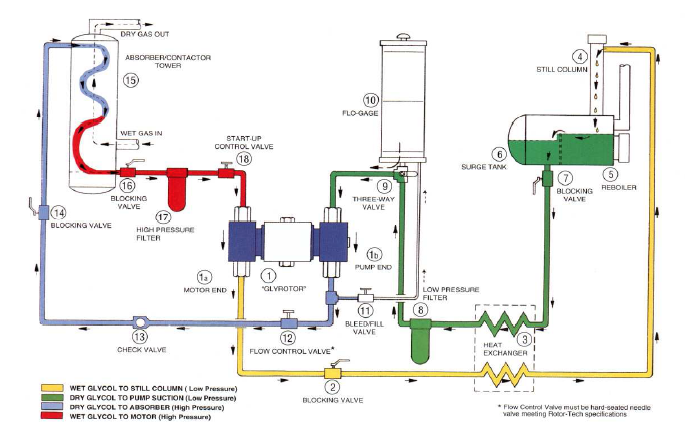

Typical Glycol Dehydrator System Schematic For Energy Exchange

This information is provided to dehydrator manufactures so the Rotor-Tech® Energy Exchange Glycol

Pump will operate correctly. Any other piping design will not do as well. If a different piping layout

is wanted, please contact Rotor-Tech’s® Engineering Department. Download pdf for full details.